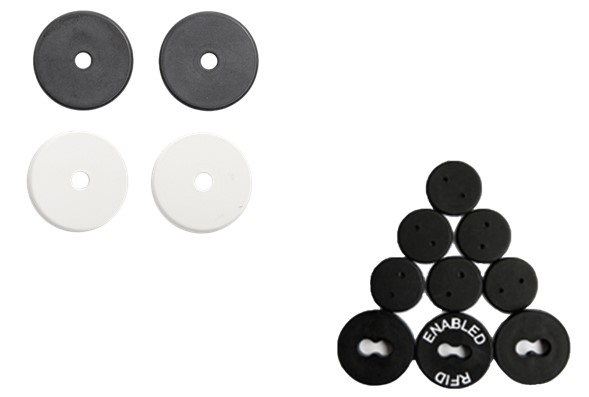

Q1. Is the tag waterproof?

A: Yes, our plastic shell RFID tags are waterproof and can operate reliably in wet environments without being affected by water.

Q2. Does the tag support multiple writes of data?

A: Yes, the tag’s built-in memory supports multiple writes of data, allowing customers to update information on the tag as needed.

Q3. What is the lifespan of the tag?

A: The lifespan of the tag depends on the usage environment and frequency, but typically it can last for several years or even longer, ensuring long-term performance and reliability.

Q4. What is the temperature range the tag can withstand?

A: Our plastic shell RFID tags can withstand temperatures ranging from -40°C to +120°C, making them suitable for use in various extreme environments.

Q5. Can the tag be used in a microwave oven?

A: It is not recommended to put the tag in a microwave oven, as the microwave may adversely affect the electronic components inside the tag, leading to performance degradation or damage.

Q6. How is the security of the tag ensured?

A: Our tags have advanced security features including password protection and data encryption, ensuring the security and integrity of data and preventing information from being tampered with or leaked.

Q7. Can the size and shape of the tag be customized?

A: Yes, we can customize the size and shape of the tag according to customer requirements to meet the needs of different application scenarios.

Q8. What should be done if the tag is damaged?

A: If the tag is damaged, it is recommended to replace it with a new tag immediately and ensure proper installation to ensure the normal operation of the system and the accuracy of the data.

Q9. How long is the lead time for customized products?

A: Based on our MOQ of 1000pcs, the delivery time is as follows: – Plastic shell RFID card: 7-9 working days after payment – RFID wristband: 10-12 working days after payment – RFID tag: 8-10 working days after payment. If you need faster or more accurate delivery, please contact our sales team for expedited service.

Q10. I don’t know the chip model I need, but I want to customize the same product, what should I do?

A: – You can send samples to us for testing, and we will produce according to your samples to ensure consistent product functionality. – Utilize a professional RFID reader to test the chip, or provide our sales team with a picture, and we will send you a sample after assessment. – If you require assistance, feel free to contact us via online chat for further support.